Flow Meter

A flow meter makes it possible to determine the flow velocity in pipes. For example, a flow meter can be used to measure the flow velocity. To do this, a pair of sensors is mounted onto the pipe to be measured. The flow meter can then determine the flow rate. Compared to other flow meters, the installation in this case is non-invasive and can be carried out without interrupting operations.

DT-TDS 200

- Measuring range ±32 m/s

- Resolution: 0,001 m/s

- Accuracy:

DN ≥50 mm: ±1.5 % rdg. for velocities > 0.3 m/s

DN <50 mm: ±3.5 % rdg. for velocities > 0.3 m/s - Reproducibility: ±0.5 % of measured value

- Operating time: approx. 10 h, LiPo battery (3.7 V, 2500 mAh)

- Protection class: IP52

This flow meter has been designed to measure the flow velocity of various media in pipes with a measuring range from about ±32 m/s. To perform the measurement, a specific acoustic velocity is required for each type of liquid. Standard liquids such as water and oils are already preset. If necessary, custom acoustic velocities can be stored.

The interface between this flow meter and a PC is via a USB-C connection. The operating time for the flow meter is approximately 10 h. The protection class für the flow meter is IP52. All values will be shown on the 2.8 inch LC display.

Request Quotation

DT-TDS 200+

- Heat Quantity Measurement

- Temperature measurement via thermocouples

- Measured Parameters: Flow velocity, volume flow, volume, temperature, thermal power, and heat quantity

- Storage Capacity: Approx. 10 million measurement points

- Cost Display: In EUR, GBP, USD, Turkish Lira, Zloty, Yen

With the Plus version of the flow meter, thermocouples can be connected. This makes it possible to determine the amount of heat in addition to flow measurement. The flow meter offers a variety of functions for this purpose.

To obtain a reference value for the amount of heat, a specific value per unit of heat can be stored, which the flow meter calculates during the measurement. This allows, for example, the extracted heat in heating systems to be determined.

The datalogger function from this device has a storage for about 10 million measuring points.

Request Quotation

DT-TDS 200 S Sensor

- Pipe Diameter: DN 15 … 100 / 20 … 108 mm

- Temperature Resistance: -30 … 160 °C

- Dimensions: 45 x 30 x 30 mm

- Mounting: Hook-and-loop fastener, magnetic

- Sensor Pair: Designed for small pipes

- Suitable For: Pipes without external coating

- Design: Compact construction

- Cleaning: Easy to clean

This sensor pair for the flow meter is designed for small pipes. The pipe diameter for this sensor pair should be between DN 15 and 100 / 20 to 108 mm. For installation, the sensors can be attached to ferromagnetic pipes, for example, using magnets.

The compact design of the sensor pair enables easy handling. Thanks to its enclosed construction, it can be cleaned quickly and easily. The sensor cable for this pair has a length of 5 m. The small and compact design (45 x 30 x 30 mm) from the sensor allows it to clean it easily. The temperatur resistance for this sensor is -30 … 160 °C and can be used for pipes without external coating.

The compact design of the sensor pair enables easy handling. Thanks to its enclosed construction, it can be cleaned quickly and easily. The sensor cable for this pair has a length of 5 m. The small and compact design (45 x 30 x 30 mm) from the sensor allows it to clean it easily. The temperatur resistance for this sensor is -30 … 160 °C and can be used for pipes without external coating.

Request Quotation

DT-TDS 200 M Sensor

- Pipe diameter: DN 50 to 700 / 57 to 720 mm

- Temperature resistance: –30 to 160 °C

- Dimensions: 70 × 40 × 40 mm

- Weight: 260 g

- Mounting options: Velcro fastener, magnetic

- Sensor pair for medium-sized pipes

- Suitable for pipes without external coating

- Compact design

This sensor pair can be used to determine the current flow rate of media in pipes with a large diameter. The pipe must have a diameter of 50 to 700 mm / 57 to 720 mm. The temperature resistance of the sensor pair ranges from -30 to 160 °C.

The sensors can be mounted using magnets on ferrous pipes. For non-ferrous pipes, they can be attached, for example, with Velcro fasteners on PVC pipes. With a weight of 260 g, the sensor pair is also very lightweight. With 530 g the sensor is very lightweight.

The sensors can be mounted using magnets on ferrous pipes. For non-ferrous pipes, they can be attached, for example, with Velcro fasteners on PVC pipes. With a weight of 260 g, the sensor pair is also very lightweight. With 530 g the sensor is very lightweight.

Request Quotation

DT-TDS 200 L Sensor

- Pipe Diameter: DN 300 … 6000

300 … 6000 mm - Temperature Resistance: -30 … 160 °C

- Dimensions: 91 x 52 x 44 mm

- Weight: 530 g

- Mounting: Hook-and-loop fastener, magnetic

- Sensor Pair: Designed for large pipes

- Suitable For: Pipes without external coating

- Design: Compact construction

The DT-TDS 200 L sensor pair is ideally suited for large pipes with dimensions ranging from DN 300 to DN 6000 / 300 to 6000 mm. Despite the size of the pipes, this sensor pair has compact dimensions of 91 × 52 × 44 mm.

For mounting the sensor pair onto the pipe to be inspected, two magnets located inside allow for effortless attachment to ferromagnetic pipes. For non-ferromagnetic pipes, such as copper pipes, hook-and-loop fasteners can also be used. The temperatur resistance from these sensors are -30 … 160 °C. This sensor ist connected to the display unit via a 5 m long sensor cable. The sensor can be placed during operation on the pipe.

For mounting the sensor pair onto the pipe to be inspected, two magnets located inside allow for effortless attachment to ferromagnetic pipes. For non-ferromagnetic pipes, such as copper pipes, hook-and-loop fasteners can also be used. The temperatur resistance from these sensors are -30 … 160 °C. This sensor ist connected to the display unit via a 5 m long sensor cable. The sensor can be placed during operation on the pipe.

Request Quotation

DT-TDS 200 SR

- Pipe diameter: DN 15 to 100 20 to 108 mm

- Temperature resistance: –30 to 160 °C

- Dimensions: 200 × 25 × 25 mm

- Weight: 250 g

- Sensor pair mounted on rails

- Mounting options: Velcro fastener, magnetic

- Sensor pair designed for small pipes

- Handle included

The sensors on the DT-TDS 200 SR sensor are mounted on a rail. This rail allows the sensors to be adjusted to fit the pipe being examined. If needed, the entire sensor assembly can be removed from one pipe and quickly and easily mounted onto another.

This makes it possible to perform multiple consecutive measurements on different pipes with ease using this sensor pair. Additionally, a handle further supports convenient handling. With a weight of just 250 g, this sensor pair is very lightweight.

This makes it possible to perform multiple consecutive measurements on different pipes with ease using this sensor pair. Additionally, a handle further supports convenient handling. With a weight of just 250 g, this sensor pair is very lightweight.

Request Quotation

DT-TDS 200 MR Sensor

- Pipe diameter: DN 50 to 700 57 to 720 mm

- Temperature resistance: –30 to 160 °C

- Dimensions: 280 × 40 × 40 mm

- Weight: 1080 g

- Sensor pair mounted on rails

- Mounting options: Velcro fastener, magnetic

- Sensor pair for medium-sized pipes

- Ruler for positioning

The DT-TDS 200 MR sensors are mounted on a rail system. Using the ruler integrated into the sensors, they can be accurately positioned for the corresponding pipe. This allows the sensors to be aligned precisely according to the pipe size.

If needed, the individual rails can be detached from the pipe and quickly transferred to another pipe to be tested, without having to reposition the sensors again. These sensors are designed for pipes with diameters ranging from DN 50 to 700 / 57 to 720 mm.

If needed, the individual rails can be detached from the pipe and quickly transferred to another pipe to be tested, without having to reposition the sensors again. These sensors are designed for pipes with diameters ranging from DN 50 to 700 / 57 to 720 mm.

Request Quotation

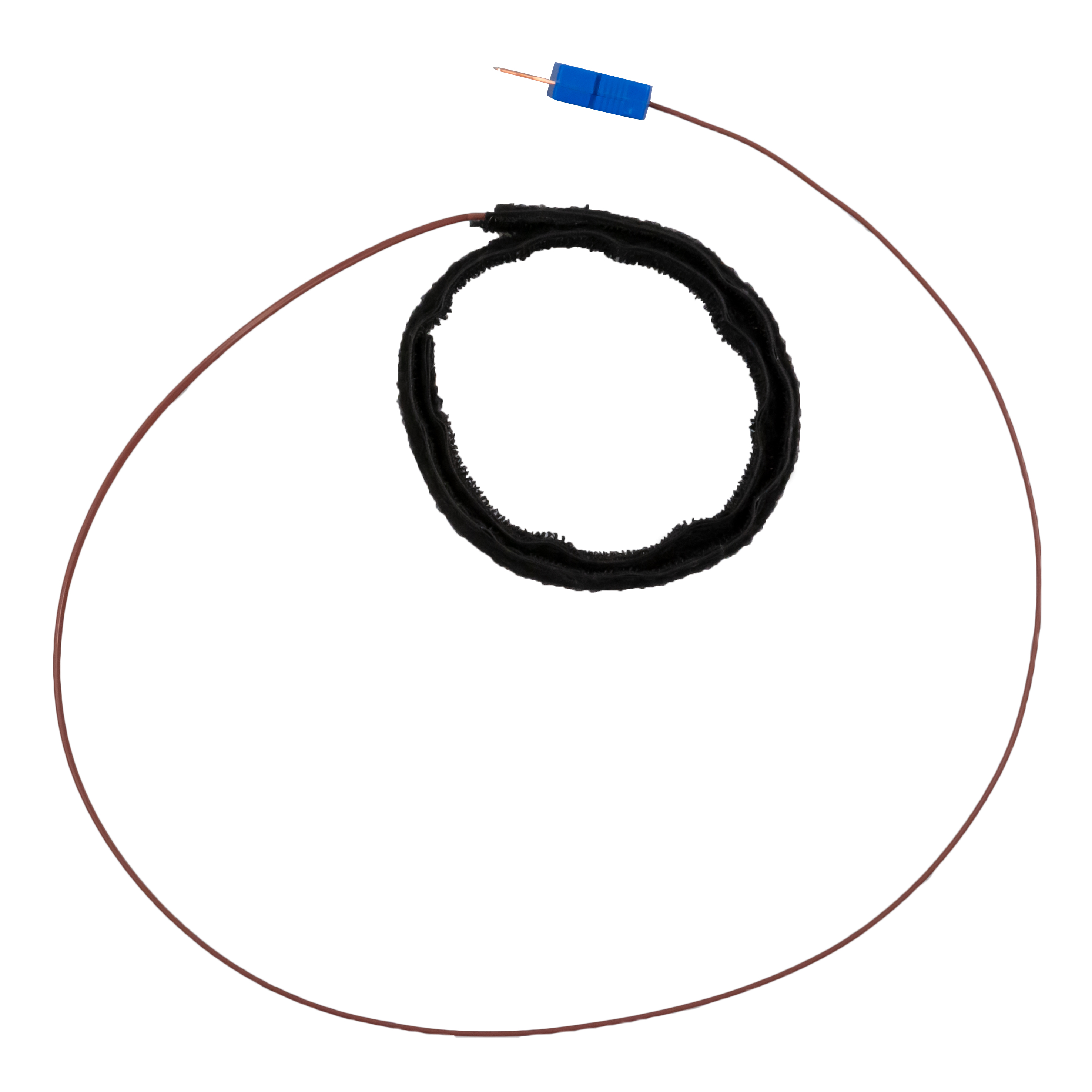

TF-RA330 Typ T

- Cable type: Teflon

- Cable length: 1, 3, 5 m

- Thermocouple: Type T

- Accuracy: 0.4% of measured value, but at least 0.5 °C

- Class: 1

- Measurement range: –270 to 400 °C

- Velcro strap length: 450 mm

- Pipe diameter: 10 to 140 mm

The TF-RA330 temperature sensors are ideal for temperature measurement. With an accuracy class of 1, these sensors offer high precision. They are required for thermal energy measurement. Thanks to a 250 mm Velcro strap, they can be securely mounted around a pipe.

This measurement is commonly used in heating systems to determine the amount of transferred thermal energy. The thermocouple operates within a temperature range of -270 to 400 °C and is available with cable lengths of 1, 3, and 5 meters. The 1 meter version is included in the DT-TDS 200+.

This measurement is commonly used in heating systems to determine the amount of transferred thermal energy. The thermocouple operates within a temperature range of -270 to 400 °C and is available with cable lengths of 1, 3, and 5 meters. The 1 meter version is included in the DT-TDS 200+.

Request Quotation